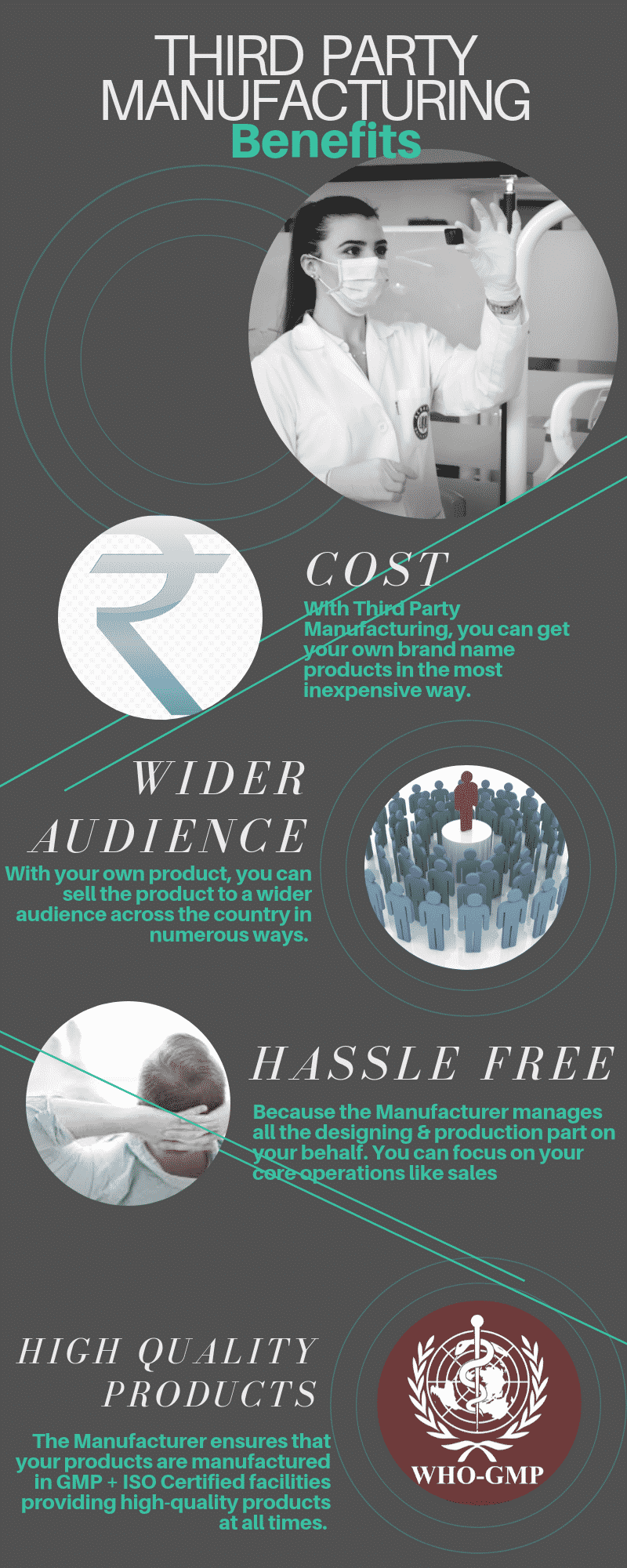

Benefits of Third Party Pharmaceutical Manufacturing

What is contract manufacturing?

Third party manufacturers are likewise alluded to as contract manufacturers. Business word reference has as great a definition as any: "Creation of products by one firm, under the name or brand of another firm. For instance, Foxconn is a third-party producer for Apple. Some organizations manufacture complex parts for different organizations, to their determination and plans. The purchasing client offers them to the public under their name and brand.

Significance contract manufacturing

Contract manufacturers give such support to several (notwithstanding competing) firms in light of their own or the clients' outlines, recipes, as well as determinations. " Third-party producers Contract maker, these have a similar importance. Toll processor implies that the first organization gives the material to the third party for transformation into the desired item.

Each of the three of these terms portrays this relationship of generation of completed products to their detail by another random organization. These contrast from the term sub-temporary worker, which implies that the sub-contractual worker completes one stage - say warm treating or covering for a producer - of parts that the main maker had created.

A notable organization may contract to have their latches (standard or specials) made by a third party manufacturer. They may do that for value reasons, for the absence of limit reasons or for ability reasons. For instance, a latch organization may make the greater part of their clasp by machining from straight steel bar stock. A request may come in requiring a latch to be created from a specific review of steel, and around then the main accessible crude material may be in a loop frame, which isn't reasonable for manufacture by machining. So, the fastener organization would have the clasp delivered by another organization (third party maker) that could cool head the steel loops into the part required on their curl bolstered chilly heading machines.

Do it yourself or outsource?

The increasing digitization and robotization are lowering the threshold to produce your own creations (possibly under supervision). Create your unique pieces or excel in craft details, then the choice is made quickly. If not, you better ask yourself what the best track is to achieve a good result. The price you have in mind, of course, also plays a role here.

The Advantages of not outsourcing third party manufacturers

o You decide for yourself whether the production process will be a success or not.

o You retain full control over your work, your reputation, and your quality.

o If you outsource the production to a third party manufacturing company, you have to make good agreements about deliveries, installments, exclusivity, …

The disadvantages of producing yourself

o Your time also costs money: weigh well whether you cannot better use the time you invest in learning to create products or projects.

o Good producers or manufacturers work much faster than you, have experience, expertise, a network and wise advice that may help you to reduce costs.

o Some producers do not only produce your work but also offer other services, such as distribution.

If your creative idea turns around a service, it is slightly easier to take matters into their own hands. After all, you do not have high production costs.